Creating solutions

R&D&I

Anudal was born out of the need to

facilitate the assembly

of aluminum window transoms, this is where the concept of the transom connection originated. In order to provide an agile service, it was necessary to manufacture in an automated way, and from there we started to develop our own machinery adapted to the needs of our manufacturing.

This is the root of our company, and it remains our working concept. Design solutions for our customers’ needs, and manufacture it in an automated way to reduce costs and manufacture quickly.

That is why our technical office develops projects for specific customer needs on a daily basis.

Our commitment is to design the solution, and to be able to manufacture it in-house.

.

At the same time, our extensive knowledge of the market allows us to identify trends and launch innovations to provide solutions to these realities.

We believe in

differentiation

and in helping our customers to be able to differentiate themselves from the market. We believe that the connecting piece should not be a limiting factor when designing an aluminum system, so we encourage the design of new systems by our customers, and that our brackets are a facilitator in the design of innovative carpentry systems.

Tailor-made design

-

Adaptation to customer profile

-

No matrix inversion

-

Small productions

-

Customization

-

Suitable for marine environments

-

100% recyclable aluminum

Anudal Industry

Anudal also has a business line for cutting and machining small extruded aluminum parts to customer design, with the possibility of manufacturing the customer’s own material. Our production capacity is more than 100,000 pieces per day.

We can perform cutting, drilling, tapping, countersinking, milling and deep drawing operations on automated machinery.

We specialize in parts from 5 to 150 mm wide, and up to 200 mm high.

Certified quality in design and production

The importance of quality in the design and production process of aluminum brackets is fundamental to guarantee the efficiency, durability and safety of these essential elements in construction and carpentry. The choice of aluminum as a material already indicates a concern for strength and lightness, but true excellence is achieved through rigorous quality control from design to manufacturing.

In the field of design, quality manifests itself in attention to detail and accuracy of specifications. Every angle, every measurement and every connection must be carefully calculated to ensure optimum performance of the brackets. In addition, the design must consider ergonomic and functional aspects, facilitating its use and adapting to various applications.

In the production process, quality becomes a constant commitment. The selection of high quality raw materials is the first step, ensuring that the aluminum used meets the appropriate standards. Manufacturing methods must be accurate and efficient, minimizing errors and ensuring uniformity in each part produced.

Quality control during manufacturing involves constant checking of the brackets for defects, imperfections or deviations from specifications.

In addition to being a crucial value for Anudal that permeates all processes, we are also certified by the ISO 9001:2015 standard, by Bureau Veritas, which ensures year after year the correct compliance with our quality standards.

Practical questions

-

This change requires a major modification of the press, with a risk that the result may not be optimal. Our recommendation is to purchase a press suitable for the type of machining to be performed.

-

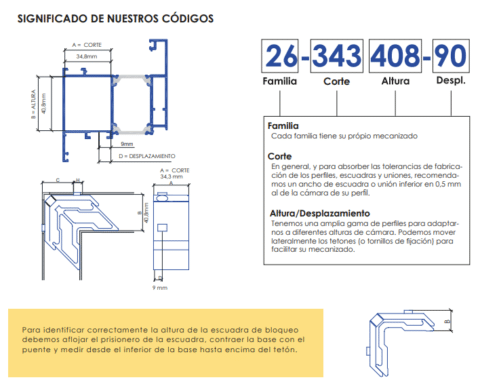

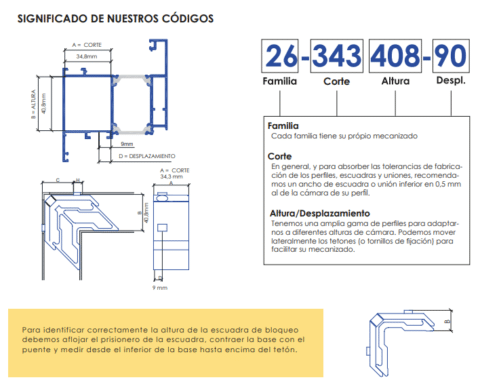

The draft distance of the bracket is the distance machined into the product according to our manufacturing systems. It is measured from the vertex of the square to the limit of the notch. The profile pull distance is the pull distance at which the profile must be machined with our presses in order to fit the nipple of our angle bracket, allowing the angle bracket to perform its function correctly!

-

It depends on whether it is a press suitable for machining the same series. If you have a press for machining Locking Angle, you cannot machine a Pivot Angle.

-

Send us a photo with a caliper measuring the cut and height of the profile or send samples directly to the Technical Office.

-

Measure with a caliper gauge the cut and the height of the profile, in the case of the Locking Bracket, the height is measured by closing the bracket to the maximum with the set screw loosened and it is measured from the base to the top of the nipple.

-

Punching machines, also called presses or dies, must be constantly lubricated. Insufficient lubrication is 90% of the causes of breakage. It is also recommended not to machine profiles larger than 2.5mm.

-

At Anudal we have what we call “the 5 golden rules for a perfect assembly”. We recommend that you always keep them in mind: 1- Cut the profiles properly at 45º. 2- Use the right punching machine 3- Check that the machining distance corresponds to the angle to be assembled. 4- Place the bracket in its original position. 5- Tighten the screw to the correct pressure before the possible deformation of the profile.